Advancements in Self-Regulating Heating Cable Technology: The Role of Polycrystalline Disc Technology and Barium Titanate (BaTiO₃)

— How PTC Ceramics Have Revolutionized the Performance and Efficiency of Self-Regulating Heating Cables —

Abstract

Polycrystalline disc technology, using barium titanate (BaTiO₃), has transformed self-regulating heating cables, offering precise thermal control and adaptability to various environmental conditions. This article focuses on how BaTiO₃'s positive temperature coefficient (PTC) properties enhance the performance of these cables, making them more efficient, durable, and capable of operating across a wide voltage range. Key benefits include voltage flexibility, consistent heat output, and suitability for demanding industries like oil, gas, and power generation. The article highlights the construction, advantages, and industrial applications of BaTiO₃-based polycrystalline disc heating cables, showcasing their role in the advancement of thermal management technology.

Introduction to Polycrystalline Barium Titanate in Self-Regulating Heating Cables

Self-regulating heating cables are an essential part of industries requiring accurate temperature control, such as freeze protection and process temperature maintenance. However, conventional systems often face limitations due to voltage sensitivity and overheating risks. Polycrystalline disc technology, powered by barium titanate (BaTiO₃), offers a breakthrough solution by providing self-limiting heat output and improved performance.

This article explores how BaTiO₃-based polycrystalline discs enable efficient, flexible, and reliable heating cables, offering advantages like wide voltage operation and durability. We examine the construction and benefits of these cables and discuss their application in industrial settings, emphasizing their role in advancing thermal management solutions.

Polycrystalline Disc Technology: A Breakthrough in Heating Systems

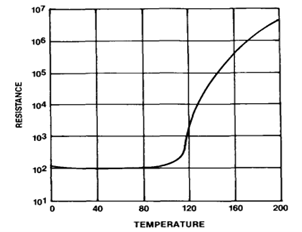

Polycrystalline power discs are a type of ceramic heating element used in self-regulating heating cables. These discs which utilize PTC ceramic technology offer a unique solution to common limitations faced by conventional heating cables. These discs are manufactured from barium titanate (BaTiO₃), a ceramic material known for its strong temperature-dependent resistance characteristics.This technology harnesses the ability of BaTiO₃ to increase its electrical resistance sharply as temperature rises, allowing for highly efficient and self-regulating heating behavior.

Traditionally, heating cables suffered from sensitivity to voltage fluctuations and high operating temperatures, which could lead to system inefficiencies or failures. In contrast, polycrystalline disc technology provides a stable and self-limiting output, where the heating element responds to changes in temperature by altering its resistance. As a result, these cables maintain optimal heating levels without the risk of overheating or system damage.

The Role of Barium Titanate in Self-Regulating Cables

At the core of polycrystalline disc technology is the use of barium titanate, a PTC ceramic material that has revolutionized the design and performance of self-regulating heating cables. Barium titanate, doped with rare earth elements, exhibits a sharp increase in resistance when the material's temperature exceeds its Curie point. Curie Point is defined as the exact reproducible temperature at which a ferromagnetic material loses its magnetism, resulting in a constant temperature until the heating coil is turned off. This property makes it ideal for applications where precise temperature control is essential.

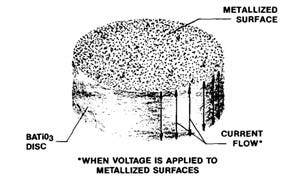

When a voltage is applied to the polycrystalline disc, the barium titanate heats up rapidly. As the disc's temperature approaches the Curie point, its resistance increases dramatically, reducing the current flow and preventing further temperature rise. This self-regulating feature ensures that the cable delivers consistent heat output, independent of fluctuations in voltage or external environmental conditions.

Construction and Performance of Polycrystalline Disc-Based Cables

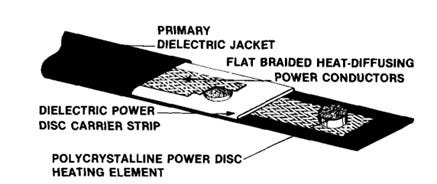

The construction of polycrystalline disc-based heating cables is designed to leverage the unique properties of barium titanate. These cables feature discs made through compression molding of BaTiO₃ with specific additives, followed by firing in an oxygen-rich environment. The metallized surfaces of the discs allow for easy electrical connection. The discs are then incorporated into a dielectric carrier strip made of high-temperature materials like perfluoroalkoxy (PFA), ensuring the cable can withstand temperatures up to 285°C.

This advanced construction technique allows polycrystalline power discs to be spaced evenly along the cable, typically at 4-inch intervals, and connected to flat braided copper conductors. The copper not only supplies power to the discs but also serves as a heat diffuser, distributing the generated heat along the length of the cable. The entire assembly is insulated with fluorinated ethylene propylene (FEP) to provide additional protection and ensure long-term durability.

Performance tests have shown that polycrystalline disc-based cables exhibit exceptional stability under various operating conditions. Whether exposed to high-voltage stress, thermal cycling, or extreme heat shock, the cables maintain their output with minimal variation. For example, tests involving cycles of alternating high-temperature steam and cold water demonstrated only a 3% change in heating output after thousands of cycles, highlighting the durability and reliability of these cables.

Benefits of BaTiO₃ in Self-Regulating Heating Cables

1. Temperature Regulation: The PTC characteristics of BaTiO₃ make it ideal for applications where temperature regulation is critical. By increasing resistance with rising temperatures, BaTiO₃ prevents overheating, ensuring that the cable delivers only the required heat.

Energy Efficiency: The self-limiting nature of BaTiO₃-based cables reduces energy consumption by adjusting the heat output according to the ambient temperature. This leads to significant energy savings, especially in applications that require long-term or continuous heating.

Voltage Independence: One of the key advantages of BaTiO₃-based cables is their ability to operate across a wide range of voltages without significant changes in performance. Whether operating at low or high voltages, the self-limiting feature remains consistent, making these cables highly versatile for various industrial applications.

Durability and Reliability: The high-temperature resistance and robust construction of BaTiO₃-based cables ensure their durability even in extreme operating conditions. These cables are designed to withstand thermal cycling, high-voltage stress, and heat shock, making them reliable for critical industrial operations.

Approval Testing for Polycrystalline Power Disc Cables

Polycrystalline power disc cables undergo several rigorous tests to ensure their safety, durability, and performance in extreme conditions. Such tests confirm the cable’s reliability for use in demanding industrial environments. These tests include:

Dielectric Test: Conducted at high temperatures (450°F) to check insulation integrity after water submersion.

Deformation and Impact Tests: Evaluated mechanical resilience under heavy load (225 lb) and impact at low temperatures (-40°F) without electrical breakdown.

Cold Bend Test: Tested flexibility at -60°F to ensure the cable’s insulation remains intact under extreme cold conditions.

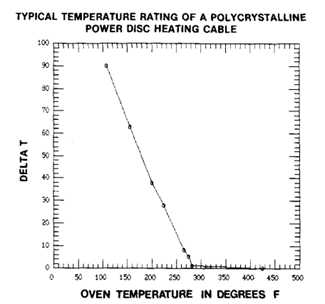

T-Rating Verification: Ensured the cable could handle different voltages (120V, 240V, 277V) without exceeding the maximum temperature rating (T-3). The test involved placing the cable in an oven and raising temperatures incrementally to verify the sheath temperature stability.

Applications of BaTiO₃-Based Self-Regulating Heating Cables

The versatility and reliability of polycrystalline BaTiO₃ have made it a cornerstone material in self-regulating electric cables used in a wide range of industries. These cables are commonly employed for freeze protection in pipelines, maintaining process temperatures in chemical plants, and providing thaw-out capabilities for process-filled piping systems. Their ability to regulate temperature without the need for complex control systems makes them an ideal solution for both industrial and commercial applications.

For example, in refineries and chemical plants, BaTiO₃-based self-regulating cables are used to maintain consistent temperatures in pipelines carrying viscous fluids or sensitive chemicals. These cables are also favored in environments where safety and energy efficiency are paramount, as their self-regulating properties minimize the risk of overheating and energy wastage. Building on the versatility and reliability of polycrystalline BaTiO₃, these self-regulating electric cables are instrumental in a variety of real-world applications:

1. 6-inch heavy distillate pipeline:

The installation of Polycrystalline Power Disc SR heating cables on a 6-inch pipeline with 1.5 inches of fiberglass insulation highlights their role in temperature control. The system maintained a consistent temperature of 120°F (49°C) through the use of a microprocessor-based powerline carrier control system, ensuring efficient operation with an output of 18 W/ft (59 W/m). This setup is a great example of how these heating cables are employed in industrial processes that require precise temperature regulation to prevent issues such as crystallization or flow restriction in pipelines.

2. Freeze protection for instrumentation level bridles:

The use of low-voltage cables for freeze protection on instrumentation level bridles demonstrates the importance of maintaining safe and functional equipment in extreme cold conditions. By using a 24-V power distribution system, this setup ensures that sensitive instrumentation is protected from freezing, a critical application in harsh environments where equipment failure could lead to significant operational issues.

Conclusion:

The Future of BaTiO₃-based SR Heating Cables

As industries continue to demand more efficient and reliable thermal management solutions, polycrystalline disc technology, powered by barium titanate ceramics, is poised to play an even larger role in the future of self-regulating heating cables. The combination of PTC ceramics with advanced cable construction techniques offers a flexible, robust solution that can meet the demands of modern industrial applications.

With ongoing research and development, the potential applications of this technology will continue to expand, offering enhanced performance and reduced costs for a wide range of industries. The ability to deliver precise, self-regulating heat output without the need for external controls positions polycrystalline disc-based cables as a key innovation in the field of electric heat tracing.

In conclusion, the integration of barium titanate-based polycrystalline disc technology in self-regulating heating cables marks a significant advancement in thermal management solutions. Its unique properties provide industries with a reliable, efficient, and adaptable heating solution, ensuring consistent performance even in the most demanding environments.

References:

Johnson, B. C., and J. E. Propst. "Technological advancement in self-limiting electric heat tracing cables." IEEE transactions on industry applications 25.6 (1989): 1006-1011 :

Mechanical stability of BaTiO3-based PTC thermistor components: experimental investigation