Calculating Required Heat-Up Power for Pipe System in Electrical Heat Tracing

While many applications of electrical heat tracing involve maintaining a specific temperature, some require an increase in temperature.

For example, bitumen is a highly viscous material. When it is not being transferred through a pipe, it can become almost solid in the ambient temperature and will not flow. To enable flow through the pipeline, the temperature must be raised to around 130°C. In this case, heat-up through electrical heat tracing is an effective solution.

In this article, I’ll explain how to calculate the required power to heat up a pipe system within a specified period of time.

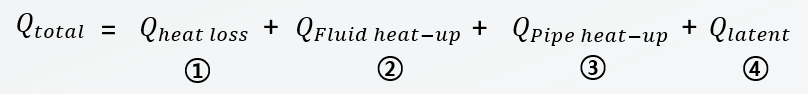

Simply put, the equation to calculate the required heat is as follows:

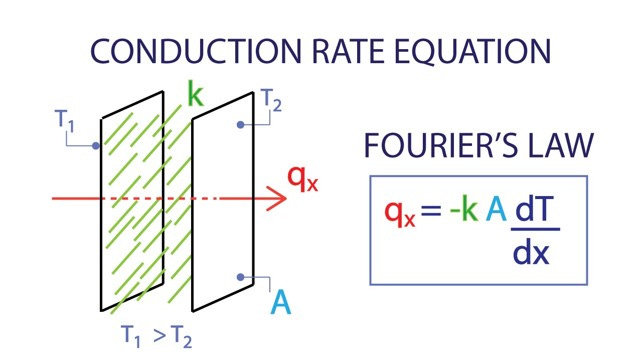

① Heat is lost from the heated pipe to the ambient environment through thermal conduction. To compensate for this loss, we need to supply an amount of heat that is equal to or greater than the heat loss.

②~③ Additionally, we need to increase the temperature of the pipe system and the fluid inside it. Therefore, we must account for the heat required to raise the temperature of both the pipe and the fluid.

④ Optionally, if there is a phase change during the heat-up process (e.g., solid to liquid, liquid to gas, or solid to gas), we should account for the additional latent heat.

Now, let’s explore how to calculate each factor to determine the total required heat.

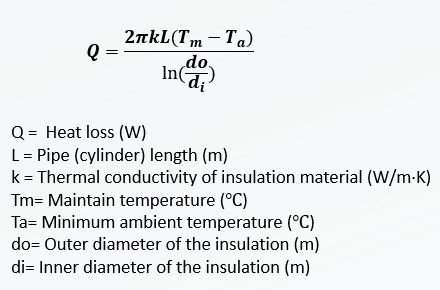

① Heat Loss (Q1)

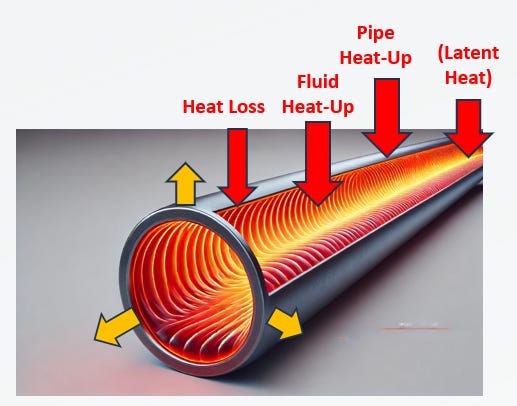

Heat is lost from the pipe through conduction, convection, and radiation. Among these, conduction is the primary cause of heat loss.

To calculate the heat loss from the pipe, we use an equation derived from Fourier’s law of heat conduction.

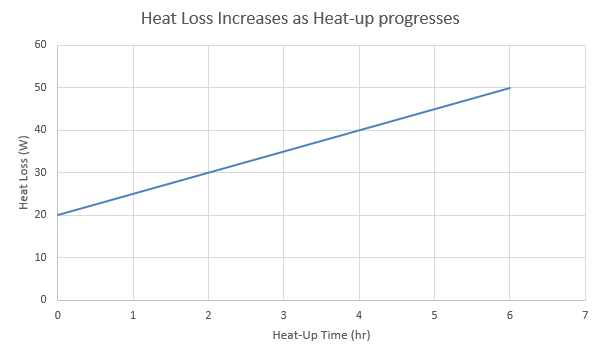

Since the heat loss (heat transfer rate) is proportional to the temperature difference, the heat loss increases as the pipe heats up.

Because heat loss is maximized once the pipe has fully heated and reached the maintenance temperature, we can determine the required heat loss as follows:

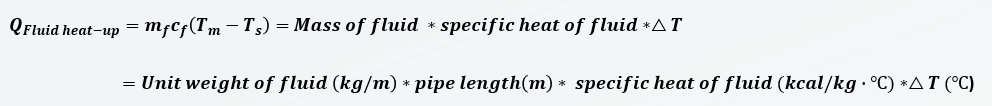

② Heat-Up for Fluid (Q2)

According to the heat capacity equation, the required heat to raise the temperature of the fluid is calculated as follows:

When calculating heat loss, we consider the maximum possible value based on the temperature difference between the maintenance temperature and the minimum ambient temperature. Given this, we can assume that the heat loss from fluid heat-up (Q for fluid heat-up) does not need to be considered separately, as the value from ① is sufficient to cover it.

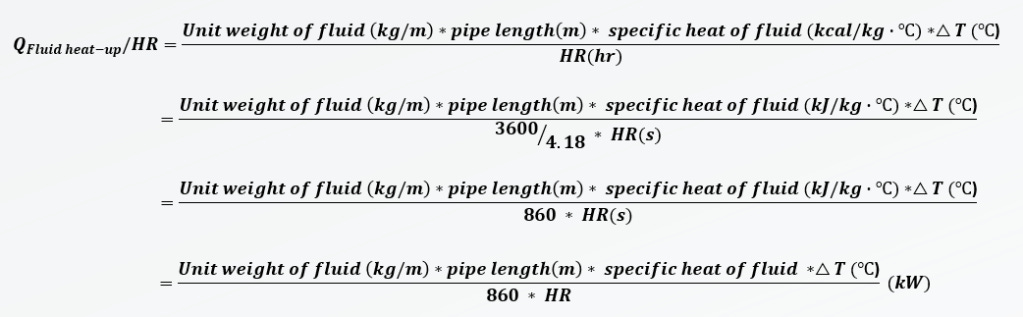

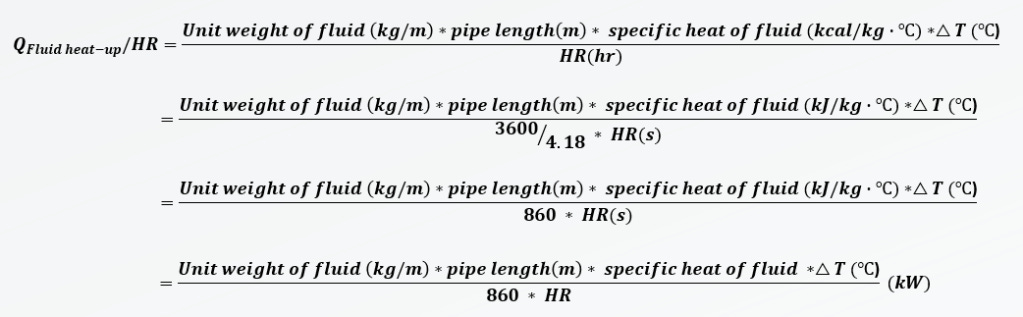

Thus, with the given time duration (HR) for the heat-up process, we can divide the required heat for fluid heat-up by the time duration.

After converting the unit values, the required heat to apply per hour is determined as follows:

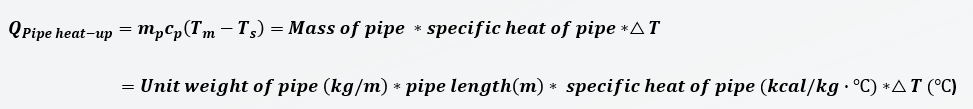

③ Heat-Up for Pipe (Q3)

We also need to account for the heat required to raise the temperature of the pipe.

Similarly, we can calculate the required heat for the pipe heat-up per hour as follows:

For steel pipes, the specific heat value is 0.11 kcal/kg°C.

Regarding the unit weight of the pipe, you can refer to the weight per meter (kg/m) for steel pipes (schedule 40, which is the standard schedule).

④ Latent heat

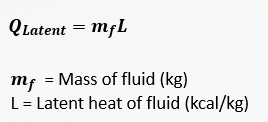

To calculate latent heat, we use the following equation:

For fusion, we use the latent heat of fusion value (L(f)), and for vaporization, we use the latent heat of vaporization value (L(v)).

By adding the values from ① + ② + ③ + ④ (heat loss + heat for fluid heat-up + heat for pipe heat-up + latent heat), we can calculate the total heat required to heat up the fluid in the pipe within the specified time duration.