Enhancing Oil and Gas Infrastructure in Extreme Environments with Self-Regulating Heating Cables

In the oil and gas industry, maintaining operational efficiency in extreme conditions is crucial. This article explores various challenges faced by oil and gas pipelines, including freezing issues, the transportation of waxy crude oil, heavy oil extraction from shallow wells, and structural integrity in LNG tank concrete structures. It highlights the role of self-regulating heating cables as an effective solution to these challenges.

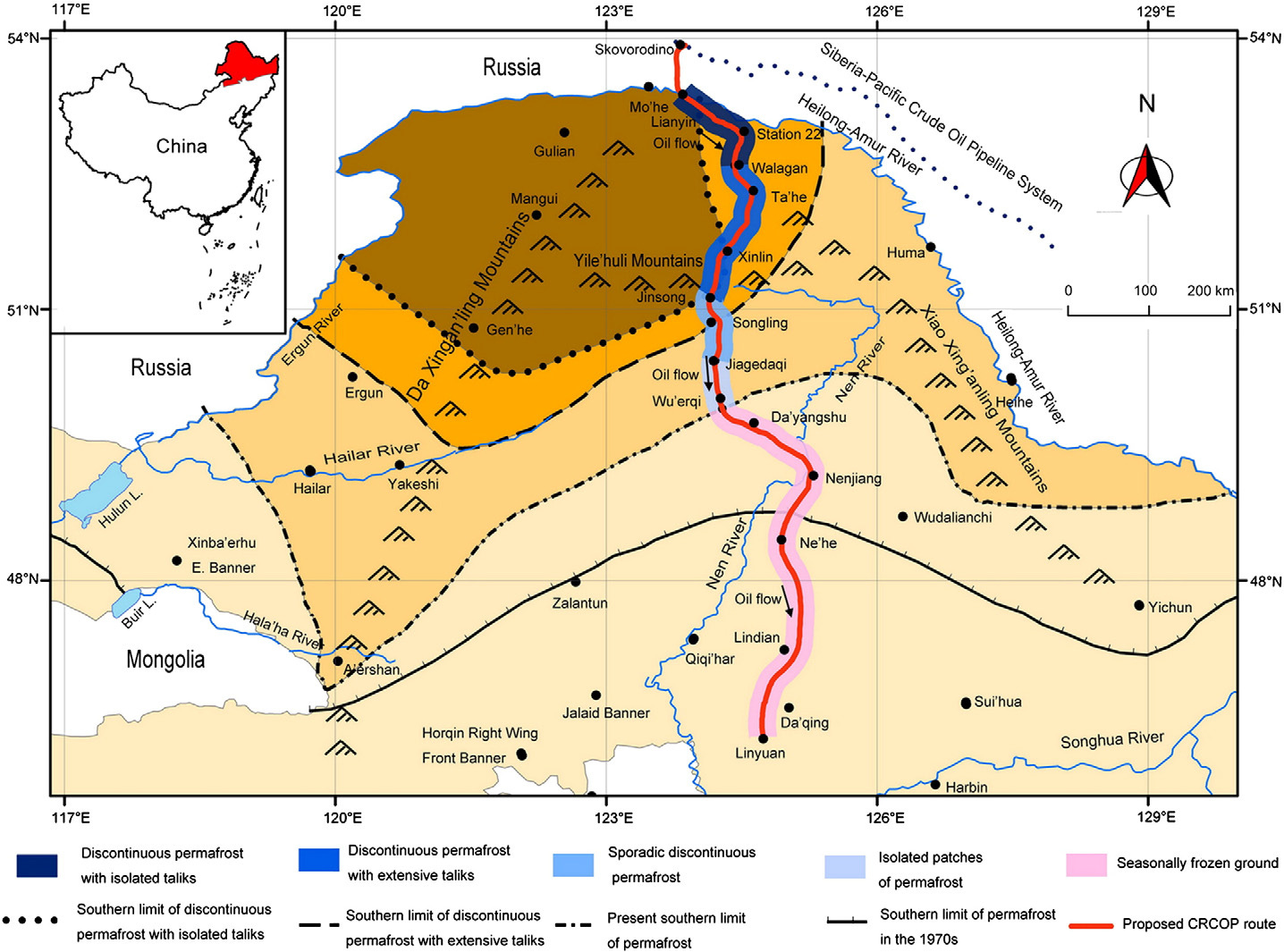

Case Study 1 : Freezing Issues in China- Russia Crude Oil Pipeline (CRCOP)

Problem: Susceptibility to Freezing

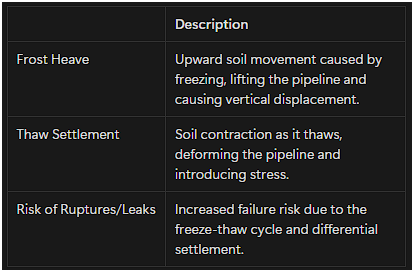

The China-Russia Crude Oil Pipeline (CRCOP), extending from Mo'he in northeastern China to Daqing, traverses approximately 500 kilometers of permafrost. This section of the pipeline faces extreme temperature variations, with winter temperatures plummeting to -52°C and summer highs reaching +30°C. The freeze-thaw cycles in this harsh environment induce frost heave and thaw settlement, creating vertical displacements and stress that threaten pipeline integrity.

During operation, the oil temperature in the CRCOP fluctuates seasonally from approximately -6°C to +25°C. These temperature shifts exacerbate soil freezing and thawing (melting ) around the pipeline, further increasing the risk of displacement. In permafrost sections, frost heave can cause the pipeline to lift by as much as 0.5 meters, while thawing results in soil contraction and settlement, potentially leading to deformations, ruptures, and leaks.

Temperature Impact on Pipeline Stability

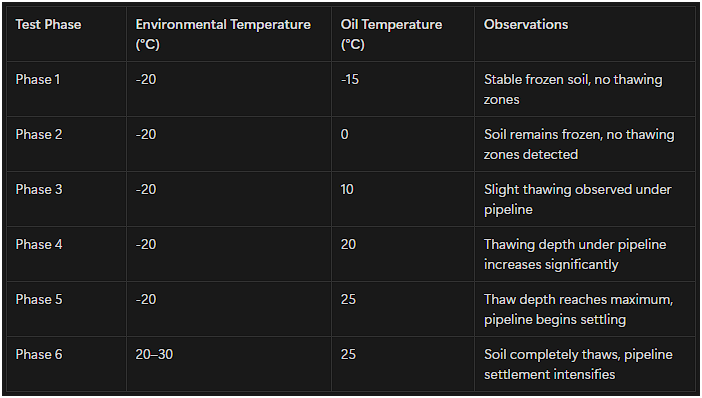

The freeze-thaw cycles around the CRCOP are illustrated in different phases, with varying oil and environmental temperatures affecting soil stability. Below are summarized temperature conditions observed during test phases to simulate CRCOP's freezing and thawing impact on the pipeline.

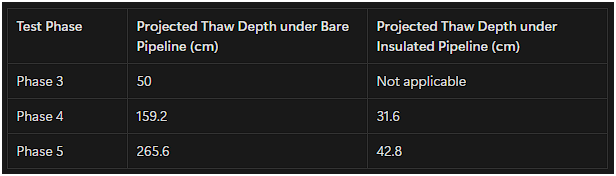

Projected Thaw Depths in CRCOP Permafrost Sections

Based on the testing model, projections were made for actual field thaw depths at different oil temperatures, taking into account the similarity ratios. These projected values provide insights into the depth of thawing and potential displacement for the CRCOP in permafrost conditions.

Solution: Self-Regulating Heating Cables

To counteract the freeze-thaw effects, self-regulating heating cables offer a proactive solution. These cables automatically adjust heat output depending on environmental temperatures, thereby stabilizing soil temperatures around the pipeline. When oil temperatures drop, the heating cables increase output to prevent freezing; when oil temperatures rise, they reduce heat output, conserving energy. This thermal control mitigates frost heave by limiting freeze-thaw cycles, stabilizing the soil, and preventing vertical displacement and stress on the pipeline. Self-regulating heating cables were specifically deployed in permafrost-affected segments, particularly in areas where the pipeline was vulnerable to freeze-thaw cycles. These cables were concentrated in sections where the soil surrounding the pipeline was most susceptible to severe temperature fluctuations, especially near river crossings, marsh areas, and regions with high ice content in the soil.

These installations targeted:

Above-Ground Segments: Self-regulating cables were applied where the pipeline emerged above ground, typically near critical infrastructure nodes like pumping stations, which required additional protection against frost damage.

Shallow-Buried Sections: The pipeline's shallow-buried segments in marsh and wetland areas received these cables to prevent the formation of frost heave, which could cause significant vertical displacement.

Transition Zones: These cables were also used in transition areas where the pipeline moved from permafrost to non-permafrost zones. This ensured a gradual change in soil temperature, minimizing differential settlement issues that arise due to abrupt freeze-thaw transitions.

Case Application: CRCOP’s Cold-Climate Solution

In the CRCOP, self-regulating heating cables could maintain stable soil temperatures, reducing frost heave impacts and preventing the formation of extensive thaw (melting) zones. This approach, especially effective in testing temperatures from -6°C to +25°C, could sustain consistent heat distribution, limiting excessive freezing and thawing (melting) in the surrounding permafrost. This solution enhances pipeline safety by addressing differential settlement and thawing depth, critical in maintaining CRCOP’s structural integrity in permafrost region.

Case Study 2 : Waxy Oil Transport Challenges In Mangala Development Pipeline (MDPL) Project in India

Problem: Waxy Crude Oil Transport

The Mangala Development Pipeline (MDPL) project in India faced a critical challenge: transporting waxy crude oil from Rajasthan to Gujarat, a distance of 600 km. The crude oil had a high wax content (up to 38%) and a Wax Appearance Temperature (WAT) between 50°C and 65°C, making it solidify at ambient temperatures. If the temperature dropped below the pour point of 32-42°C, the oil would gel, making transportation impossible without continuous heating.

Solution: Heat Tracing System

To address this challenge, a comprehensive heating system was deployed, primarily relying on the Skin Effect Heat Management System (SEHMS) for long stretches of the pipeline. However, in areas where SEHMS was impractical—such as short, above-ground pipeline segments at the 36 pumping and heating stations—Self-Regulating Heating Cables (SRHC) were strategically implemented to supplement heating.

Usage of Self-Regulating Heating Cables in Above-Ground Segments

In the MDPL project, SRHCs were crucial for ensuring temperature control in above-ground sections at stations located approximately every 20 km along the route. These stations required localized heating due to environmental exposure and potential heat loss, which could lead to cooling below the WAT if not addressed. The SRHCs provided an effective solution for these shorter segments, where they could adjust their output according to ambient temperature, providing more heat in colder conditions and less in warmer ones.

Results and Success

The project was a resounding success, becoming the world's longest heated pipeline at the time. The combination of heating and insulation enabled the safe and reliable transport of 200,000 barrels of oil per day, with a pipeline availability rate of 99% over the first three years. The innovative use of SEHMS technology and self-regulating heating cables proved to be crucial in solving the transportation challenges posed by the waxy crude.

This approach highlights the adaptability and reliability of self-regulating heating cables in scenarios where short-range, temperature-sensitive heating is needed to support uninterrupted pipeline operations in the oil and gas industry.

Freeze Protection System on a North Sea Offshore Platform

Background

An offshore platform located in the North Sea operates in extreme weather conditions, where winter temperatures frequently drop to -20°C. These sub-zero temperatures put various systems at risk of freezing, posing operational and safety challenges.

Problem: Susceptibility to Freezing

Essential systems on the platform, particularly piping networks, faced risks from extreme cold:

Freezing of Pipes: In such temperatures, water and other liquids in pipes are likely to freeze, compromising system functionality.

Operational Reliability: The risk of freeze-related failures in remote and harsh environments poses significant safety and operational concerns.

Solution: Self-Regulating Heating Cables

To mitigate freezing, nVent RAYCHEM self-regulating heating cables and the NGC-30 multi-circuit control and monitoring system were installed. This setup included:

Temperature Control: The self-regulating heating cables adjust their output based on ambient temperature, maintaining pipes above freezing even in extreme cold.

Monitoring and Control: The NGC-30 system provides remote monitoring and control, ensuring energy-efficient operation by activating the heating only as needed.

Data and Results

The installation of SR heating cables delivered several benefits:

Temperature Consistency: Continuous monitoring confirmed that pipe temperatures were kept above freezing, ensuring uninterrupted functionality throughout winter.

Energy Efficiency: The system conserved energy by dynamically adjusting output, reducing power consumption compared to constant-output systems.

Enhanced Reliability: Freeze protection ensured operational reliability, reducing risks associated with frozen systems.

Outcome

The freeze protection system enhanced the platform’s resilience and operational efficiency, demonstrating the effectiveness of advanced heating solutions in maintaining safety and reliability in challenging offshore environments.

Freezing and Structural Integrity in LNG Tank Concrete Structures

Problem: Structural Challenges in LNG Tanks

In offshore LNG (Liquefied Natural Gas) tanks, the extreme cryogenic conditions (-165°C for LNG storage) pose significant challenges to the surrounding concrete structures. These temperatures can lead to frost formation in the concrete base slab and walls, causing frost heave, cracking, and loss of structural integrity. This is particularly concerning for Gravity Based Structures (GBS), where the concrete foundation supports the weight of massive LNG tanks.

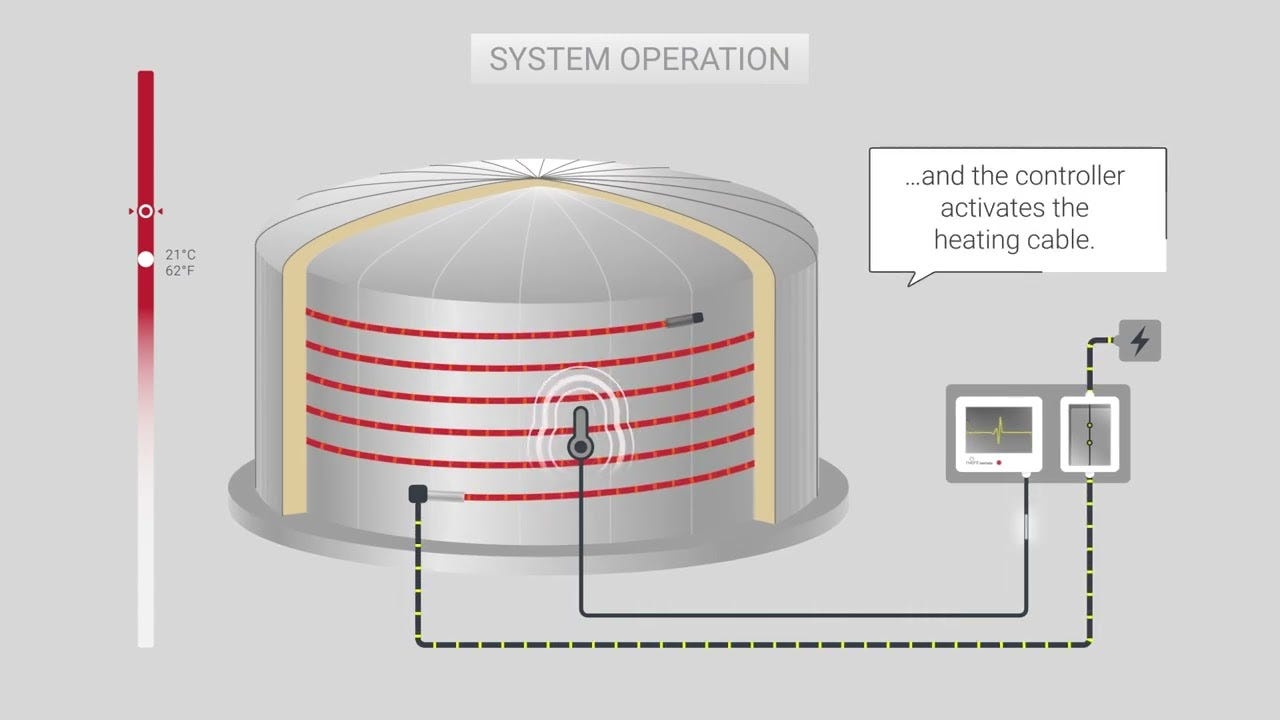

Solution: Self-Regulating Heating Cables

Self-regulating heating cables provide an effective solution by maintaining stable temperatures in the concrete structure. Embedded within the base slab and walls, these cables adjust their heat output automatically based on the surrounding conditions, preventing frost formation while ensuring that energy is used efficiently.

The cables operate as follows:

Embedded Installation: The heating cables are installed in ducts or tubes within the concrete walls and base slab. This design ensures that the entire surface is evenly heated, preventing any localized freezing points.

Temperature Control: Self-regulating cables adjust their power output based on the temperature of the surrounding material. This feature is crucial for structures with varying temperatures, such as submerged parts of the GBS (exposed to cold seawater) and sections above water exposed to ambient air.

Redundancy: The heating system is designed with redundancy, meaning that if one cable fails, the adjacent circuits continue functioning, preventing the temperature from dropping below critical levels.

Example of Use

In a typical installation, the cables are embedded throughout the slab and walls of the concrete structure. Temperature sensors are distributed across the structure, feeding data into control panels that adjust the heating system as needed. If a section of the concrete cools below the set point, the cables heat that area, preventing any frost heave or cracks. This targeted heating approach ensures efficient energy use and maintains the integrity of the entire LNG tank structure.

Advantages Over Other Heating Methods

Compared to traditional constant wattage heating systems, self-regulating cables offer significant advantages:

Energy Efficiency: Because they adjust power output based on real-time temperature data, self-regulating cables only use energy where and when it is needed.

Reduced Maintenance: These cables have a longer lifespan due to their ability to regulate heat automatically, reducing the risk of overheating and cable failure.

Simplified Installation: Self-regulating cables can be cut to length on-site, which simplifies installation in large concrete structures.

This technology ensures that Gravity Based Structures (GBS) supporting LNG tanks maintain their structural integrity, preventing costly damages caused by freezing temperatures.

Conclusion

Self-regulating heating cables emerge as a critical technology across various applications in the oil and gas industry. From enhancing pipeline integrity in freezing conditions to ensuring reliable waxy oil transport, optimizing heavy oil extraction, and maintaining structural integrity in LNG tanks, these cables provide energy-efficient, cost-effective solutions that significantly enhance operational reliability and safety. The versatility of self-regulating heating cables illustrates their essential role in overcoming the unique challenges faced by the oil and gas sector in extreme conditions. Following is the brief conclusion of what we have seen so far as the applications in of SRHC in Oil and Gas Sector.

Freezing Issues in Oil Pipelines

Problem: Susceptibility to freezing due to extreme environmental conditions, leading to frost heave and thaw settlement.

Feature: Self-regulating heating cables that automatically adjust their heat output based on surrounding temperatures to prevent freezing.

Temperature Range: -6°C to +25°C (China-Russia Crude Oil Pipeline).

Waxy Oil Transport Challenges

Problem: The solidification of waxy crude oil during transportation, making it impossible to flow below the pour point.

Feature: Self-regulating heating cables combined with a skin effect heat management system (SEHMS) to maintain temperatures above the Wax Appearance Temperature (WAT).

Temperature Range: 50°C to 65°C (Mangala Development Pipeline).

Freeze Protection Systems in Offshore Platforms

Problem: Freezing of water supply in sprinkler lines.

Feature: Self-regulating heating cables that maintain the pipe temperature within a consistent range, preventing water from freezing.

Temperature Range: 5°C to 10°C (Offshore Oil Platform in Norway).

Structural Integrity in LNG Tank Concrete Structures

Problem: Frost formation and potential structural damage due to cryogenic temperatures in LNG tanks.

Feature: Embedded self-regulating heating cables that maintain stable temperatures in the concrete, preventing frost formation.

Temperature Range: -165°C (LNG Tanks).