The Science of Self-Regulation: How Molecular Structure Change Controls Heat Output

Abstract

This article explores the molecular science behind self-regulating heating cables, revealing how they adapt their heat output based on temperature. Through thermal expansion, contraction, and conductive pathways within a polymer-carbon matrix, these cables automatically adjust conductivity to regulate heat, maximizing energy efficiency. The dynamic molecular changes, explained by percolation theory and Joule heating, allow the cables to increase heat in cold conditions and reduce it when warmer. This innovative self-regulation minimizes energy waste and offers robust temperature control in industrial applications.

Purpose

The purpose of this article is to provide an in-depth explanation of how self-regulating heating cables function at the molecular level. It aims to educate readers on the science behind the adaptive heat output mechanism, highlighting how these cables automatically adjust their resistance based on temperature changes.

Self-regulating heating cables represent an advanced solution in temperature management, commonly used in industrial and residential applications. At the core of their efficiency lies the ability to adjust heat output automatically, a process rooted in molecular-level adjustments. These cables can increase or decrease their thermal output in response to the surrounding temperature, a feat achieved through a clever interplay of materials science and thermodynamics.

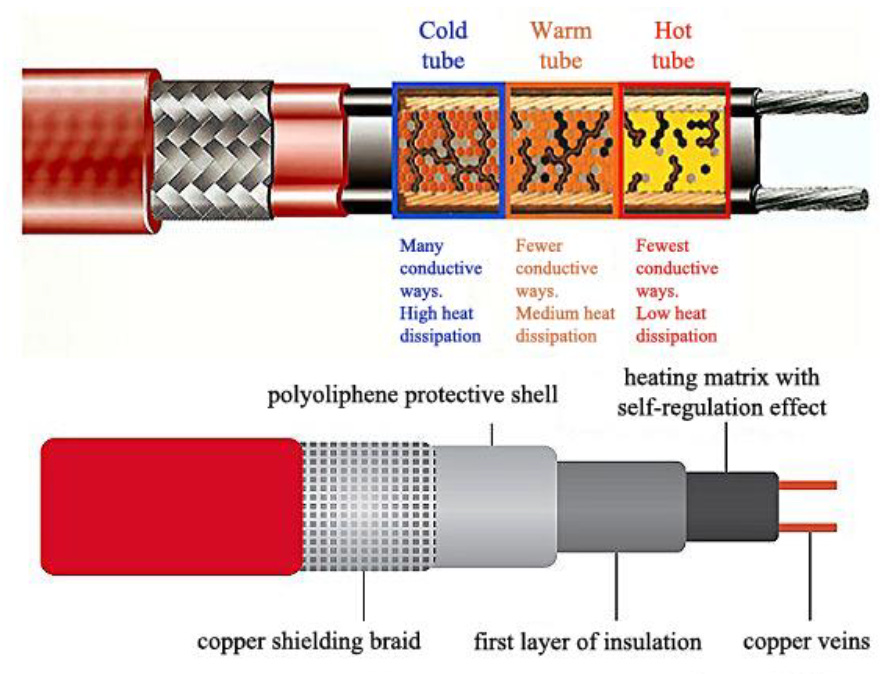

Understanding the Core Mechanism: The Role of the Polymer Matrix

The key to the self-regulation process is the polymer matrix embedded with conductive elements, usually carbon-based particles. The polymer is designed to undergo structural changes at the molecular level as the temperature fluctuates. These molecular adjustments affect the electrical conductivity of the material, which in turn regulates heat output. The polymer is typically composed of semiconductor material/ thermosensitive materials that enable automatic heat adjustment based on temperature.

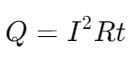

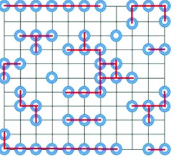

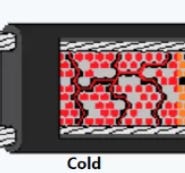

At Low Temperatures: When the ambient temperature drops, the polymer contracts, bringing the carbon particles closer together. As the carbon particles come into closer contact, the electrical conductivity increases, allowing more current to pass through. This results in an increased heat output, ensuring the system maintains the required temperature.

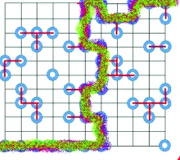

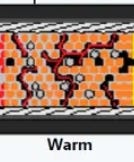

At High Temperatures: Conversely, as the surrounding temperature rises, the polymer expands. This expansion separates the carbon particles, reducing the electrical conductivity of the material. With less current flowing through the cable, the heat output decreases, preventing overheating and improving energy efficiency.

This dynamic behavior is central to the cable's ability to adjust heat output automatically without external controls or sensors.

But what are the underlying molecular phenomena responsible for these changes?

Thermal Expansion and Contraction

At the molecular level, one of the primary phenomena driving the self-regulation process is thermal expansion and contraction of the polymer matrix. As temperature increases, the vibrational energy of the polymer molecules increases, causing the material to expand. This expansion disrupts the conductive pathways between carbon particles, reducing current flow. When the temperature decreases, the reverse happens: the polymer molecules lose energy, contract, and restore the conductive pathways. This cycle of expansion and contraction is a direct response to the surrounding thermal environment, allowing the cable to self-regulate.

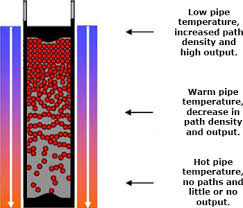

Percolation Theory

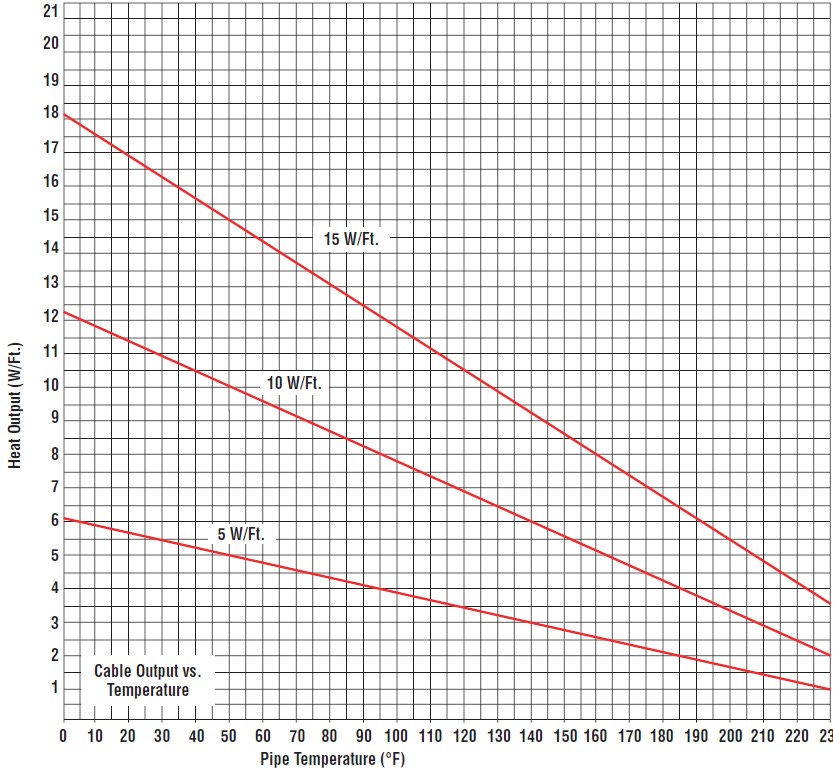

Percolation theory helps explain the conductivity changes in self-regulating heating cables. In the polymer-carbon composite, carbon particles act as conductive fillers.

Phenomena: As the polymer matrix expands or contracts, the connectivity between these particles changes, affecting the overall electrical conductivity. Percolation theory describes how, at a critical threshold (the percolation threshold), the number of conductive pathways sharply increases or decreases, creating a non-linear response to temperature changes. When carbon particles are close enough, the system reaches a critical point where conductivity spikes, allowing more current and heat production.

Interpretation of Regions in the Graph and behavior of SR cables at those regions

Filler Content

Filler content refers to the amount or concentration of conductive particles (like carbon) embedded within a polymer matrix. In self-regulating heating cables, these fillers are crucial for creating conductive pathways that allow current flow and heat generation. As temperature changes, the polymer matrix around the fillers expands or contracts, altering the distance between conductive particles.

Transport properties

Transport properties in the graph typically refer to how well the material conducts electricity (or heat) based on the connectivity of the conductive fillers. For SR cables, transport properties reflect the cable’s conductive behavior—its ability to allow or restrict the flow of electric current. Higher transport properties indicate a high level of conductivity, leading to more heat output. Lower transport properties signify restricted conductivity, resulting in less heat

Above Graph illustrating the transport properties of a material relative to the percolation threshold fc(fc is a percolation threshold after which conductive properties of polymer changes and we get non linear behavior)

Below fc(Blue curve):

The material has low conductivity as the conductive fillers are dispersed and do not form continuous pathways corresponding to lower temperature. At low filler content, transport properties increase slowly.

Response of Self-Regulating Cables to Lower Conductivity in Polymer Matrix(due to low temperature) When the polymer matrix of an SR cable has low conductivity due to lower temperatures, it increases the number of conductive pathways to raise heat output. At these lower temperatures, polymer molecules within the cable contract, increasing molecular density and enhancing conductive filler pathways. This densification allows the cable to produce higher power output, compensating for the colder conditions and ensuring efficient heat generation.

Behavior of Self-Regulating Cables at Low Temperatures: Increment of Conductive Pathways

At fc:

At the critical threshold fc, the material's conductivity begins to increase significantly due to the initial formation of a connected network of conductive fillers. This point represents the transition phase, where conductive pathways start to form, allowing moderate current flow and leading to an increase in temperature, but not yet at its maximum.

Response of Self-Regulating Cables at Critical Conductivity Threshold in Polymer Matrix

When the polymer matrix of an SR cable reaches the critical conductivity threshold (fc, conductive pathways begin to form but are not fully developed. The SR cable responds by increasing its power output moderately, which gradually raises the temperature to meet the warming requirements in colder conditions. This phase represents the cable’s adaptive response to provide additional heat as the conductivity begins to rise.

Behavior of Self-Regulating Cables at Moderate Conductivity Levels

At fc, SR cables operate in a balanced mode, where partial conductivity enables moderate heating. This transitional state allows the cable to adaptively increase temperature while maintaining control, preparing for either higher output in colder conditions or reduced output as temperature rises further.

at fc (warm temperatures), green line is representing conductive pathway(at fc conductive pathways are start to form)

After fc(Red Curve):

Red curve representing material reaches high conductivity due to a well-connected network of conductive fillers, allowing efficient current flow. Hence representing Higher temperature.

Response of Self-Regulating Cables to Higher Conductivity in Polymer Matrix(due to high temperature) When the polymer matrix of an SR cable has high conductivity due to higher temperatures, SR cable decreases the number of conductive pathways. This allows the cable to produce lower power output, compensating for the extreme or hotter conditions and ensuring efficient heat reduction.

Behavior of Self-Regulating Cables at High Temperatures: Reduction of Conductive Pathways

Joule Heating (Resistive Heating)

Joule heating, also known as resistive heating, is the process by which electrical energy is converted into heat as it passes through a conductive material. In self-regulating cables, the conductive carbon particles embedded within the polymer matrix generate heat when current flows through them. As the molecular adjustments reduce conductivity at higher temperatures, less current passes through the cable, reducing the heat generated by the resistive effect. The opposite happens at low temperatures, where increased conductivity leads to more resistive heating.

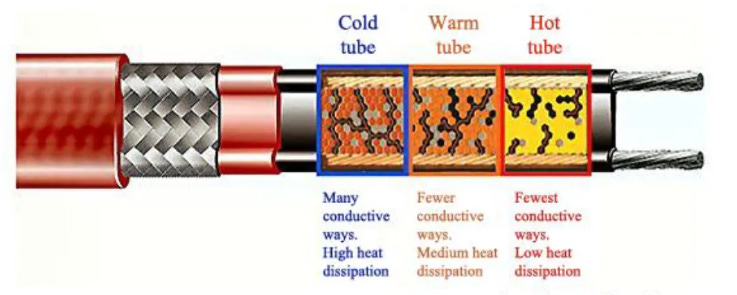

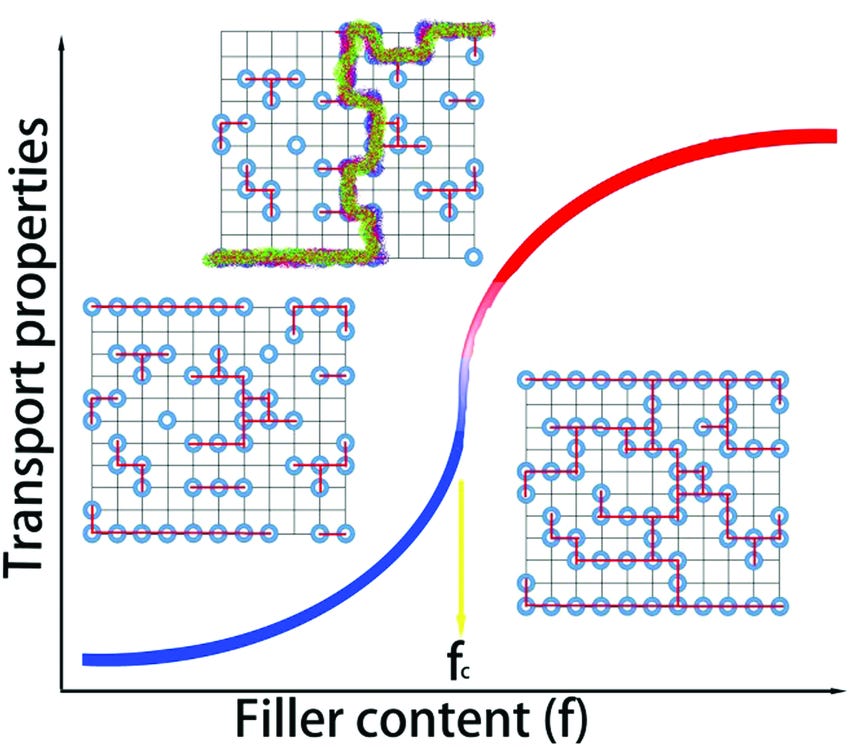

The formula of joule heating is:

Hence all these phenomenon make up entire molecular adjustments in self regulating cable which you can see in the image. Image shows how the polymer matrix, embedded with conductive particles (such as carbon), changes its structure based on temperature, affecting the heat output.

How Molecular Adjustments Enhance Energy Efficiency

The molecular adjustments within the semiconductive polymer enable the heating cable to respond dynamically to its environment. This adaptive capability not only enhances performance but also contributes to significant energy efficiency:

At lower temperatures, when heat demand is high, the semiconductive polymer contracts, increasing current flow and maximizing heat output. This ensures that the cable maintains a warm environment even in colder conditions.

At higher temperatures, the polymer expands, reducing conductivity and minimizing heat output. This prevents the system from overheating and consuming unnecessary energy.

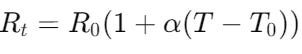

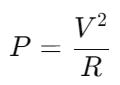

The output change in terms of temperature change can be illustrated through the graph and equations involved in this output change are:

Where:

Rt = Resistance at temperature T

R0 = Resistance at a reference temperature T0

α= Temperature coefficient of resistance (per degree Celsius)

This equation shows how the resistance of the self-regulating cable changes with temperature, directly impacting the heat output. Therefore, while the heating cable does not switch off once the target temperature is reached, it adjusts its power output based on the temperature of the heated medium, providing consistent protection against freezing conditions.

Conclusion

Self-regulating cables emerge as the unsung heroes of modern heating technology. By intelligently adjusting their output on a molecular level, they provide seamless, reliable, and energy-efficient protection, even in the most demanding conditions. These cables don't just react—they adapt, maintaining the delicate balance needed to prevent freezing without wasting energy. As we continue to innovate in the field of energy management, understanding the science behind these remarkable systems reminds us of the power of simple, yet elegant, solutions. Self-regulation isn't just a feature—it's a revolution in heat control.